Price differences in pickleball paddles are more than branding—they reflect differences in material quality, engineering standards, production processes, and certification readiness.

Cheap paddles typically use basic cores and surface materials with limited control and durability, while premium paddles rely on carbon faces, precision molding, and consistent tournament-grade performance.

When launching or expanding paddle lines, understanding these differences ensures better positioning in both entry-level and competitive markets. Partnering with capable factories ensures stability and performance across large-scale orders.

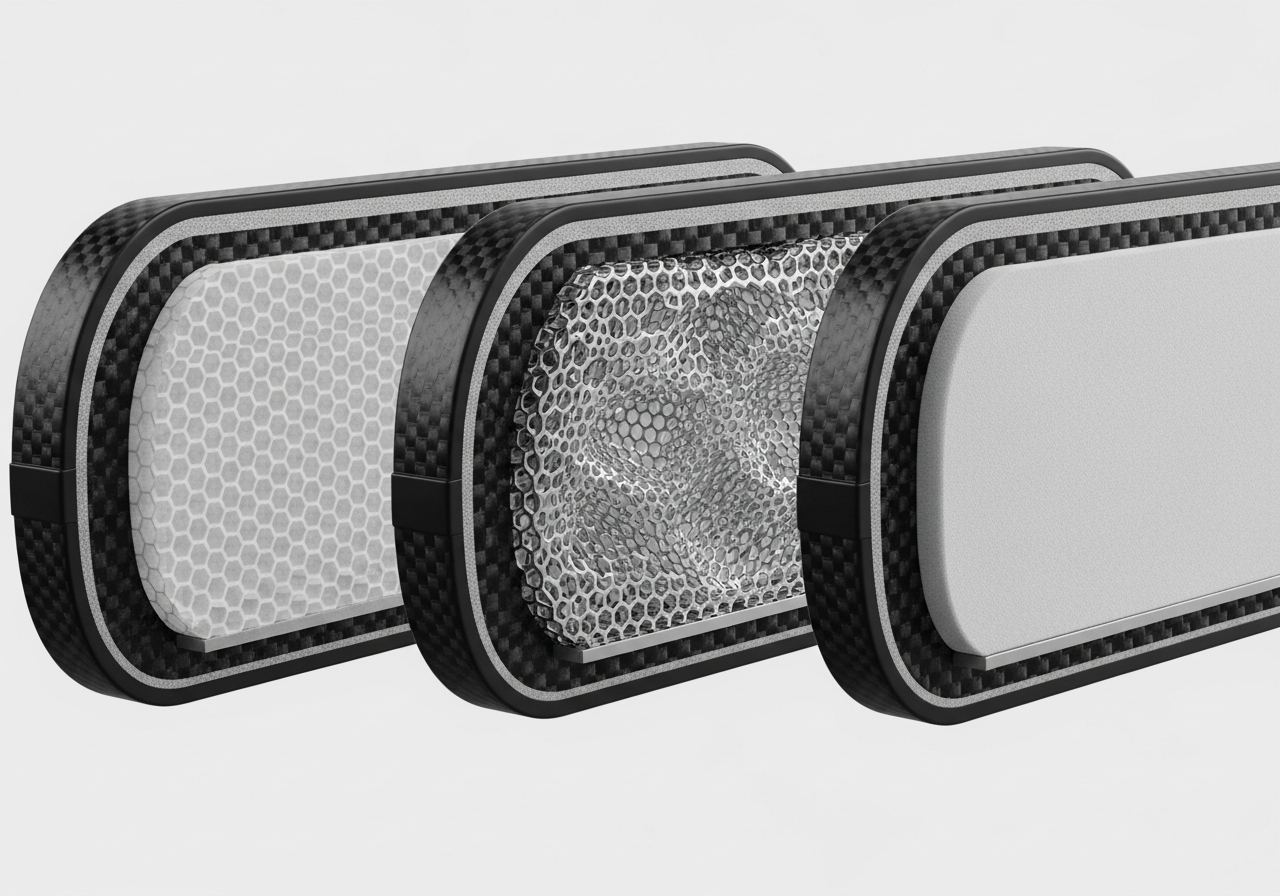

How does the internal core structure vary?

The core affects paddle control, rebound, noise level, and weight. Material selection and core design are key indicators of cost-performance balance.

Low-end paddles often feature low-density or recycled polymer cores, while high-end paddles adopt premium polypropylene honeycomb cores with calibrated compression and higher durability.

| Core Type | Description | Used In |

|---|---|---|

| EVA Foam | Soft, low rebound | Toy-grade paddles |

| Recycled Polymer | Inconsistent density | Budget paddles |

| PP Honeycomb | Balanced and quiet | Mid-level models |

| Premium PP Core | Durable, consistent compression | High-end paddles |

Advanced manufacturing uses precision extrusion, CNC-cutting, and vacuum pressing to maintain consistent structure and energy transfer. This is rarely found in budget-oriented production lines.

How does face material influence price and performance?

The face material determines feel, spin potential, vibration control, and longevity. Surface construction separates low-end products from professional-standard paddles.

Entry-level paddles use smooth plastics or PET faces, while high-performance models feature fiberglass or multi-layer carbon fiber faces.

| Face Material | Characteristics | Application Segment |

|---|---|---|

| ABS/PET | Glossy, smooth, low friction | Cheap promotional use |

| Fiberglass | Moderate texture, power-focused | Intermediate players |

| 3K–18K Carbon Fiber | Rigid, spin-enhancing, low vibration | Competitive segment |

High-end factories apply grit coatings or sandblast textures under heat-press conditions to increase surface control and durability. These treatments are rarely available in low-cost paddle assembly.

What production processes define paddle quality?

Beyond raw materials, the difference lies in manufacturing execution—mold precision, bonding strength, balance adjustment, and edge finishing.

Premium paddles are produced using compression molding, vacuum lamination, and laser-cut shaping for exact tolerances and smooth feel.

| Process Step | Budget Version | Premium Version |

|---|---|---|

| Molding | Manual, open-air glue | Closed mold compression |

| Surface Lamination | Hand-applied sheets | Heated vacuum bonding |

| Balance Calibration | Estimated by weight | Precision set with digital scales |

| Quality Control | Visual only | Multi-point QC + bounce test + polish |

The result is visible in both visual alignment and on-court performance consistency. Premium paddles maintain the same feel from batch to batch, crucial for brand loyalty.

How does paddle performance differ during real use?

Players can easily feel differences during use—especially in competitive settings where control, spin, and precision are essential.

Cheap paddles tend to produce more vibration, less spin, and inconsistent bounce across the face. High-end paddles maintain stable response, soft feel, and superior control.

Key factors influenced by materials and structure:

- Vibration control: Enhanced in carbon-faced paddles with soft EVA edge buffers.

- Sweet spot size: Larger and more consistent with engineered cores.

- Spin generation: Boosted by textured carbon or grit surfaces.

- Sound level: Softer impact sound from polymer honeycomb vs. hard pop in Nomex or budget cores.

Well-designed paddles reduce wrist fatigue and enhance player confidence, especially in longer match sessions.

Are there certification and compliance differences?

Paddles intended for competition must pass testing by regulatory bodies such as the USAPA. Most budget paddles fail to meet these standards.

Only paddles with calibrated deflection, friction, and surface specs can be USAPA-approved. High-end production lines meet these criteria through precision tooling and material control.

| Certification Area | Budget Paddle Challenges | Premium Paddle Advantages |

|---|---|---|

| Deflection Limits | Inconsistent under pressure | Lab-tested for bounce uniformity |

| Surface Roughness | Too smooth or unregulated | Sanded/treated to meet friction limits |

| Structural Integrity | Glue failure common | Reinforced bonding and edge protection |

Premium manufacturers offer full documentation, lab testing support, and batch traceability—features rarely supported by low-tier suppliers.

Conclusion

The gap between cheap and expensive pickleball paddles is defined by core material, surface technology, manufacturing precision, and performance certification. Low-cost models may suit casual use, but they lack the consistency and structural quality required for serious play or brand scaling.

When selecting paddle suppliers or planning new product launches, focusing on controlled materials, verified processes, and customizable molds is the most reliable way to ensure product value matches player expectations.

📩 For technical support, sample evaluation, or custom production plans, contact the Youth Padel engineering team at hu@miao-ke.com or WhatsApp: +86-13023656973. Support is available for OEM/ODM projects, private label launches, and competitive paddle development.