The paint and coating process is an essential part of badminton racket manufacturing. Not only does it enhance the racket's aesthetic appeal, but it also improves durability and performance. In this guide, we’ll walk through how the paint and coating process is done, from preparation to the final finish.

Paint and coating play a crucial role in both the appearance and longevity of a badminton racket. Let’s explore how this process is executed to create a premium racket.

In the manufacturing of a badminton racket, the paint and coating process isn’t just about adding color. It involves several steps that protect the racket’s frame, improve grip, and ensure that the racket performs at its best. Here's a closer look at how it all comes together.

Preparing the Racket Frame

Before the paint and coating are applied, the racket frame must be properly prepared to ensure adhesion and durability of the finish.

Surface preparation is critical to ensure the paint adheres properly and the final coat lasts longer.

The racket frame, typically made of carbon fiber, graphite, or aluminum, is first cleaned to remove any dust, oils, or impurities. This is done using a combination of chemical cleaners and abrasives to roughen the surface slightly. Roughening the surface ensures that the paint adheres better, improving the durability of the finish.

After cleaning and surface treatment, the racket is inspected for any defects. Imperfections like small cracks or chips in the frame are addressed before moving to the next step. This ensures that the racket is ready for the painting process.

Applying the Base Coat

The base coat is the first layer applied to the racket. This layer provides the initial color, helps with adhesion, and contributes to the racket’s overall durability.

The base coat helps seal the frame and prepares the racket for further layers of paint and coating.

The base coat is usually a thin, even layer of paint that is sprayed onto the prepared frame. It is often white or light-colored, depending on the design of the racket. This base layer serves as a primer for the top coat and provides a smooth foundation that enhances the final finish.

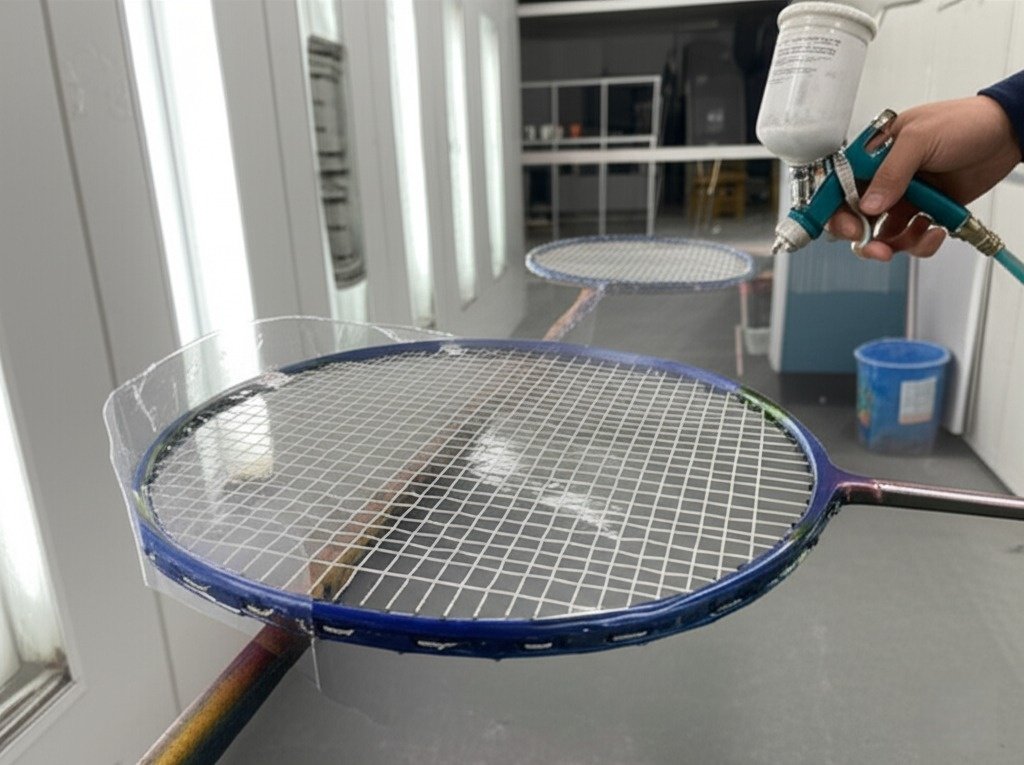

During the application of the base coat, special equipment such as airbrush systems or spray guns is used to ensure an even coating. The rackets are typically placed in a drying chamber to cure the base coat, ensuring that it adheres properly to the frame.

Adding the Color Layer

Once the base coat has dried and cured, the color layer is applied. This layer adds the distinctive color and design to the racket, contributing to its aesthetic appeal.

The color layer not only enhances the look of the racket but also helps protect the underlying frame.

The color layer is applied using similar methods as the base coat. It can be a single color or multiple colors, depending on the racket design. In some cases, decals or patterns are applied during this stage to create custom designs. These designs are carefully masked off to ensure clean lines and avoid overspray.

Once the color layer is applied, the racket is again placed in a curing chamber to ensure proper drying. This layer is essential not just for the appearance of the racket but also for providing an additional protective layer against scratches and other forms of wear.

Applying the Clear Coat

The clear coat is the final protective layer applied to the badminton racket. This layer is crucial in providing a high-gloss finish, adding durability, and protecting the color layer from wear and tear.

The clear coat provides a glossy finish and acts as a barrier against scratches, UV damage, and moisture.

The clear coat is usually a transparent, durable coating applied over the color layer. It provides an extra layer of protection and gives the racket its shiny, polished appearance. The clear coat is typically made from a polyurethane or acrylic resin, which is highly resistant to wear and tear, UV rays, and environmental elements.

The clear coat is applied in several thin layers to ensure an even finish. After the clear coat is applied, the racket is once again cured in a drying chamber to harden and set the finish. This ensures that the coating remains intact and maintains its gloss for an extended period.

Curing and Drying Process

After each layer of paint and coating is applied, the racket undergoes a curing process to ensure that each layer is fully set and hardened. The curing process is critical to the final quality of the racket’s finish.

Curing helps the paint and coatings adhere properly and gives the racket its final strength and durability.

The curing process typically involves placing the rackets in an oven or a curing chamber. The heat accelerates the drying process, ensuring that each layer of paint or coating becomes solid and well-bonded to the frame. Curing also ensures that the final coating can withstand impact, wear, and exposure to environmental factors like moisture or heat.

The length and temperature of the curing process are carefully controlled to ensure that the racket does not overheat or become damaged during the drying process.

Final Inspection and Quality Control

Once the painting and coating process is complete, the rackets undergo a final inspection to ensure the quality of the finish. This step is crucial to ensure that the racket meets the manufacturer’s standards.

Quality control ensures that each racket has a flawless finish and is free from defects before it reaches the customer.

The final inspection involves checking for defects such as uneven paint, chips, or imperfections in the clear coat. The racket is also checked for consistency in color and gloss. Any imperfections or defects are corrected before the racket is packaged and sent to market.

Rackets that pass the inspection are then packaged and prepared for shipping. The packaging is designed to protect the racket from any damage during transit, ensuring that customers receive a product that is in pristine condition.

Conclusion

The paint and coating process in badminton racket manufacturing is essential for both the appearance and durability of the racket. From surface preparation to the final clear coat, each step ensures that the racket looks great, performs well, and lasts longer. Understanding this process helps you appreciate the craftsmanship and technology behind your favorite badminton racket.