Selecting the best padel racket depends on a player’s experience, stroke development, and tactical preferences. The right combination of shape, weight, materials, EVA core, and surface structure ensures stability, comfort, and predictable performance.

The most effective racket is one that aligns technical specifications with playing level and style, supported by consistent factory engineering.

This guidance supports brand owners, distributors, retailers, clubs, and manufacturing partners when organizing product categories or designing rackets tailored to different user groups.

Which Racket Shape Fits Different Playing Levels?

Shape influences control, forgiveness, and power. Each design suits a distinct playing need.

Round Shape

Best for developing players seeking stability and large sweet-spot forgiveness.

The low balance improves maneuverability and reduces handling complexity.

Teardrop Shape

Ideal for progressing players who need balanced attack and defense.

This design shifts the sweet spot slightly higher, offering both control and power.

Diamond Shape

Suited for advanced players with strong technique and powerful impact.

The high-balance structure produces explosive overheads and deep volleys.

Inside the factory, mold precision and temperature-controlled curing maintain shape accuracy. Uniform geometry ensures consistent sweet-spot behavior across all units in a series.

How Should Weight Be Chosen for Each Level and Style?

Weight directly affects swing speed, stability, and comfort.

340–355g

Recommended for beginners or players emphasizing maneuverability and fast reaction.

Lightweight options limit fatigue during long sessions.

355–370g

Ideal for intermediate or advanced players needing stronger stability and powerful shot output.

This range supports aggressive play and more confident finishing.

Factory weight control relies on automated carbon cutting, calibrated resin application, and digital inspection. These procedures maintain consistent weight distribution across every production batch.

How Do Materials Influence Playing Style?

Material selection defines racket stiffness, vibration behavior, and impact feel.

Fiberglass

Elastic and forgiving, suitable for developing players who need soft impact sensation.

Hybrid Carbon–Fiberglass

Balanced stiffness and comfort, ideal for versatile playing styles.

High-Grade Carbon (3K, 12K, 18K, 24K)

Provides strong rigidity and precision for players with advanced control and powerful strokes.

In manufacturing, material layers must be aligned accurately. Controlled storage conditions preserve resin quality, while calibrated curing ensures bonding integrity. These factors create predictable stiffness and impact behavior.

How Does EVA Core Density Affect Level and Style?

EVA core density influences rebound, ball exit speed, and comfort.

Soft EVA

Suitable for developing players; offers comfort and stability during inconsistent contact.

Medium EVA

Balanced response for players seeking both control and crisp energy return.

Hard EVA

Designed for advanced players generating natural power; delivers quick rebound and sharper touch.

EVA density is determined in factory compression molds. Temperature, pressure, and durometer testing ensure identical rebound characteristics for every racket in a product line.

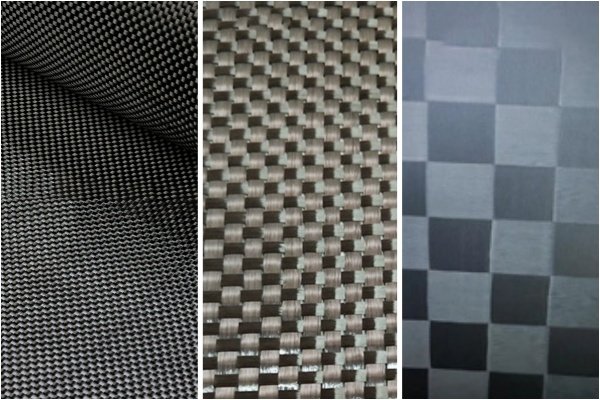

How Does Surface Texture Support Playing Style?

Texture affects spin ability, grip on the ball, and overall shot control.

Smooth Surface

Best for developing players needing predictable ball release.

Fine-Sand Texture

Suitable for players who mix control with moderate spin.

Rough Texture

Designed for advanced shotmakers who rely heavily on spin variations.

Factories apply surface texture through heat-press embossing, mold-integrated patterns, or controlled spraying systems. Consistent roughness is essential to maintain reliable performance across units.

Conclusion

The best padel racket depends on aligning shape, weight, materials, EVA density, and texture with a player’s level and playing style. A round, lighter, softer model suits developing users; a balanced teardrop or hybrid model benefits versatile intermediate players; and a stiff, well-reinforced diamond shape serves advanced competitors.

Stable factory engineering—including calibrated curing, CNC mold accuracy, controlled material processing, and strict quality inspection—ensures each racket delivers its intended performance across large orders. These production strengths support brand owners, distributors, retailers, clubs, and manufacturing partners building structured and reliable product lines.