Quality control is a critical aspect of racket manufacturing, ensuring that every product meets performance, safety, and durability standards. In this guide, we’ll walk you through the steps involved in quality control and how manufacturers ensure each racket is up to par before it reaches the market.

Quality control in racket manufacturing ensures that every racket meets the desired standards for performance, safety, and durability, guaranteeing a great experience for the player.

Quality control involves several steps and rigorous testing procedures that focus on ensuring the performance, durability, and consistency of the racket. Let’s dive into the processes that guarantee high-quality rackets.

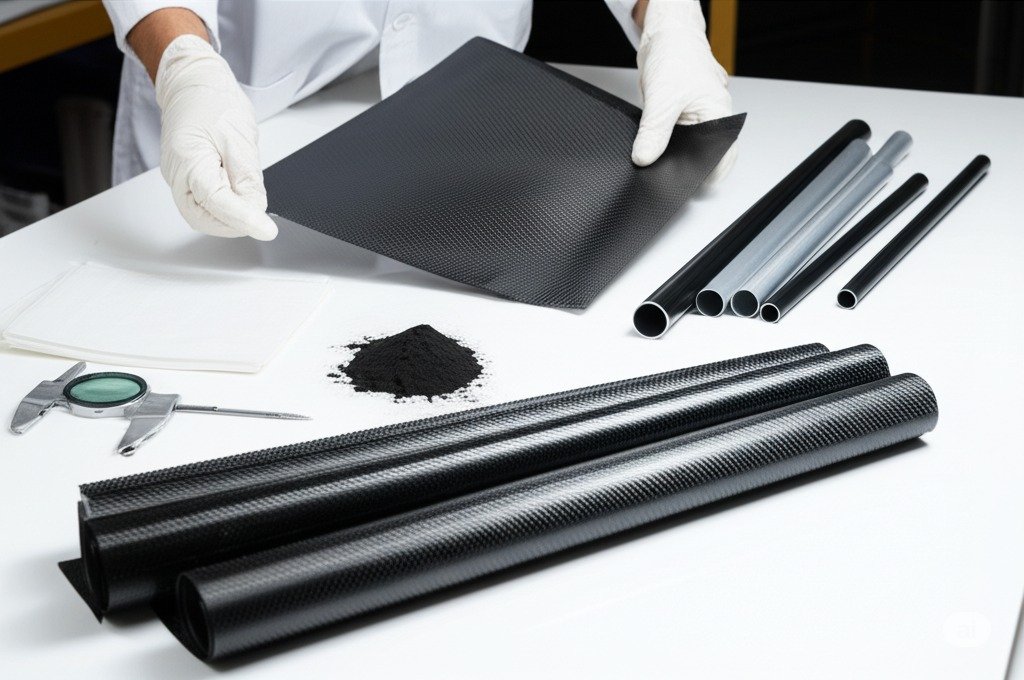

Material Inspection

The first step in quality control begins with inspecting the raw materials used in manufacturing the racket. The quality of materials such as carbon fiber, graphite, aluminum, and plastic plays a vital role in the final performance and durability of the racket.

Proper inspection of materials is essential to ensure that only high-quality materials are used in the production of the racket.

Manufacturers start by sourcing materials from trusted suppliers. These materials are checked for consistency, strength, and uniformity. For instance, carbon fiber and graphite used in the frame are tested for their tensile strength, flexibility, and weight. If any material is found to have imperfections or does not meet the required specifications, it is rejected or sent back to the supplier for replacement.

Similarly, the grip material is checked for softness, durability, and the ability to withstand wear. Only materials that meet specific standards are used in the final product.

Frame and Shaft Quality Check

After the materials are approved, the next step involves quality control checks on the racket’s frame and shaft. This step ensures that the frame is free from any cracks, defects, or inconsistencies in weight and balance.

Ensuring the frame and shaft are free from defects is crucial to prevent breakage and ensure optimal performance during play.

Once the frame and shaft are constructed, they undergo thorough inspection. The frame is checked for structural integrity, ensuring there are no weak spots or cracks that could affect performance or lead to breakage. The shaft is also checked for uniformity, ensuring that it meets the desired level of stiffness or flexibility based on the racket’s design.

Advanced testing methods, like X-ray scanning or ultrasonic inspection, may be used to detect internal cracks or weak points that are not visible to the naked eye. These inspections are essential for ensuring the racket can withstand the stresses placed on it during intense gameplay.

Stringing and Tension Testing

One of the most critical aspects of racket quality control is the stringing process. The tension of the strings directly affects the performance, power, and control of the racket. Incorrect string tension can drastically alter the feel of the racket and its ability to hit the shuttle effectively.

Stringing and tension testing ensure that the racket performs consistently and meets the desired specifications.

After the frame is strung, the racket is tested for string tension. String tension is carefully measured and adjusted using string tension gauges, ensuring that it falls within the desired range. High-end rackets typically have a more precise stringing process, as the tension can vary depending on the player’s needs and style of play.

The string pattern is also checked to ensure it aligns correctly with the design. A dense pattern provides more control, while an open pattern gives more power and comfort. Any discrepancies in string tension or pattern are immediately corrected.

Weight and Balance Testing

The weight and balance of a racket have a huge impact on how it performs. A well-balanced racket helps the player control shots, while the weight affects the power generated during play.

Precise weight and balance testing ensures that the racket performs as intended, catering to different playing styles.

Manufacturers use high-precision scales to measure the weight of each racket to ensure consistency across batches. The weight is typically measured in grams, with most badminton rackets ranging from 70 to 100 grams.

Balance testing is just as critical. Rackets can be head-heavy, head-light, or evenly balanced, and each design serves a different purpose. To ensure proper balance, the racket is placed on a balance scale, and its distribution of weight is verified. This step ensures that the racket will provide the desired power or control based on its intended use.

Paint and Coating Inspection

Once the racket is assembled, it goes through a detailed inspection of the paint and coating. The paint not only enhances the racket’s appearance but also serves a functional purpose by adding a protective layer against scratches, UV damage, and wear from repeated use.

Paint and coating inspections ensure the aesthetic finish is flawless and that the racket is durable under constant use.

After the frame is painted and coated, it is carefully inspected for consistency in color and gloss. Any inconsistencies in the coating, such as bubbles or uneven coverage, are addressed by repainting the racket. In addition to appearance, the paint layer is also tested for durability. The racket is subjected to scratch and abrasion tests to ensure that the coating can withstand the wear and tear of regular play.

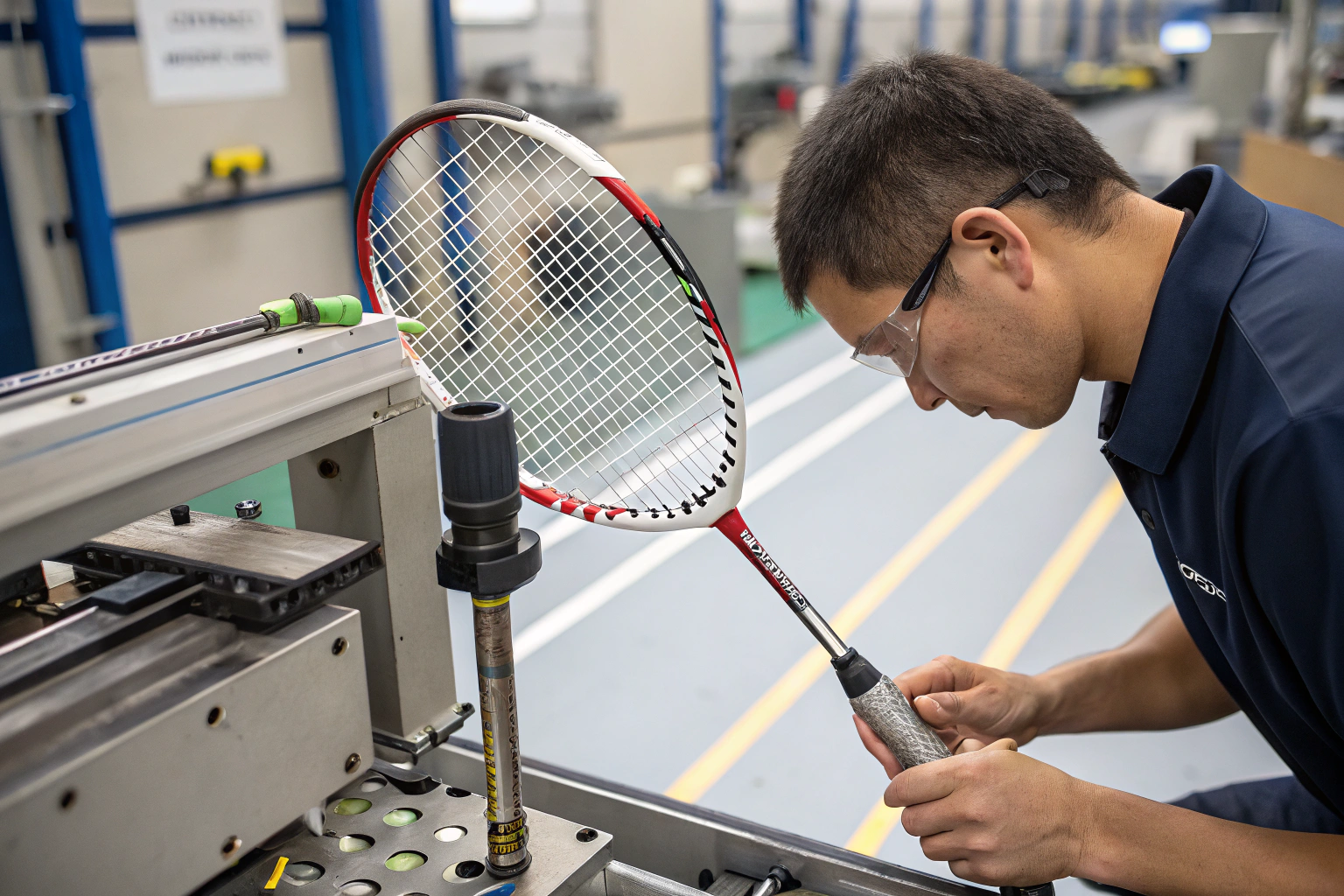

Final Functional Testing

Once all the individual components pass their respective inspections, the racket undergoes functional testing. This step ensures that the racket performs to its highest potential and meets the standards set by the manufacturer.

Functional testing ensures that the racket behaves as expected during play, with all components working in harmony.

During functional testing, rackets are tested under realistic playing conditions. Testers may perform strokes, smashes, and volleys to evaluate how the racket performs in terms of power, control, comfort, and durability. These tests simulate the pressure and strain that the racket will experience during actual play.

The testing phase may also involve stress tests to check how well the racket can withstand impacts, prolonged use, and environmental changes (such as humidity or temperature variations).

Conclusion

Quality control in racket manufacturing is a multi-step process that ensures every racket is built to perform at its best. From material inspection to final functional testing, each step guarantees that the racket meets high standards for durability, performance, and comfort. By focusing on quality control, manufacturers ensure that every player receives a racket that is both reliable and enjoyable to use.