A high-quality padel racket depends on its structural engineering, materials, weight distribution, and factory manufacturing precision. These elements directly determine stability, control, durability, and overall playing comfort.

A better padel racket delivers consistent impact response, reliable vibration control, and long-term structural strength supported by advanced production processes.

This information supports brand owners, distributors, retailers, clubs, and manufacturing partners when evaluating performance tiers or developing upgraded product lines.

How Do Materials Influence Overall Racket Quality?

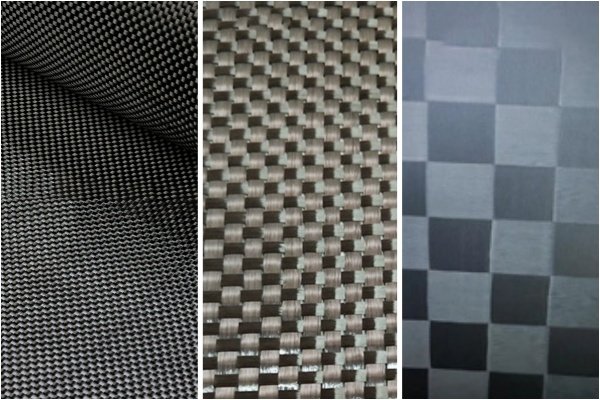

The selection of carbon grade, fiberglass elasticity, and hybrid layup structure strongly impacts power, control, and vibration behavior.

Higher-grade carbon fibers—such as 12K, 18K, or 24K—provide increased stiffness and superior energy transfer. These fibers resist deformation at impact, creating cleaner ball output and improved directional accuracy. Fiberglass adds flexibility and comfort, making it suitable for models requiring softer feel. Hybrid constructions balance stiffness, durability, and playability.

In the factory, materials are stored in controlled environments to preserve resin quality. Automated cutting machines ensure consistent fiber orientation, while technicians follow engineered layup sequences designed to deliver uniform stiffness zones. These processes allow the racket to behave predictably throughout its lifespan.

How Does Weight and Balance Improve Playing Performance?

Weight distribution determines maneuverability, shot stability, and player endurance.

A well-balanced racket enables smooth transitions between defensive and offensive movements. Lighter models offer quicker reaction time, while slightly heavier constructions generate stronger power through momentum. The key factor is balance placement—head-heavy rackets support powerful overheads, whereas head-light designs boost control and speed.

Factory calibration ensures accurate weight placement using digital scales and adjustment processes during final assembly. This precision prevents variability across production batches, supporting consistent performance for retailers, clubs, and large-scale product programs.

How Does EVA Core Density Enhance Playing Feel?

The EVA core acts as the power and comfort engine of the racket.

Soft EVA produces a smooth, forgiving sensation suitable for controlled gameplay. Medium EVA balances rebound speed with predictable feel. Hard EVA delivers sharp ball exit and explosive power.

Inside the factory, EVA cores are produced through pressure-controlled compression molding. Temperature and pressure determine final density, while durometer testing verifies uniform hardness. Accurate core engineering ensures identical rebound characteristics across every racket in a series.

Why Is Surface Texture Important?

Surface texture affects spin capability, ball grip, and contact stability.

Smooth surfaces provide predictable ball release and easy control. Fine-sand textures offer moderate grip for controlled spin. Rough textures generate strong rotation but require refined technique.

Factory finishing determines surface consistency. Automated spraying systems, patterned molds, or heat-press embossing create uniform texture levels. Consistent finishing ensures that entire product lines maintain identical feel, which is essential for club and retail programs.

How Do Manufacturing Processes Determine Racket Quality?

A padel racket becomes “better” when structural engineering combines with precise and stable factory processes.

Quality begins with CNC-engineered molds that preserve accurate geometry. Carbon layups must follow controlled patterns, ensuring synchronized flexibility across the frame. Curing ovens operate at calibrated temperatures to activate resin systems and prevent deformation.

After curing, each frame enters finishing workshops where sanding, polishing, painting, and surface inspection are performed. Balance control, stiffness measurement, and structural evaluation ensure the final racket meets performance standards. These processes reduce defect rates and ensure predictable quality across large orders.

Why Do Some Rackets Maintain Performance Longer?

Longevity depends on reinforced structural zones, bonding strength, and material fatigue resistance.

Frames built with multi-layer carbon systems maintain stiffness over time. Enhanced resin bonding prevents internal separation, while reinforced bridge and shoulder areas increase impact resistance. A better racket remains stable across repeated high-intensity sessions without losing power or control.

Durability is especially important for clubs, distributors, and retailers supplying high-usage environments where equipment must remain reliable over long periods.

Conclusion

A better padel racket is defined by its material quality, weight balance, EVA core engineering, surface texture, and manufacturing precision. When these factors align through advanced production techniques—such as CNC mold fabrication, controlled curing, structured carbon layup, and thorough inspection—the result is a racket with superior control, power stability, comfort, and durability.

Reliable factory systems ensure consistent performance across large orders, supporting brand owners, distributors, retailers, clubs, and manufacturing partners in building competitive product lines and long-term cooperation within international markets.