With over 10 years of expertise, our factory specializes in high-performance carbon fiber padel rackets. Precision engineering ensures exceptional power, control, and durability — built for serious play.

Create your own custom padel racket with personalized design, weight, balance, and materials. Ideal for players seeking performance and style tailored to their game.

Want to customize a padel racket? DinkPadel helps turn your concept into reality. We guide you through the development process, avoiding common pitfalls to ensure your custom padel rackets are delivered on time, on budget, and with the quality your brand demands.

Sourcing padel rackets for your brand? We offer a streamlined private label solution — from custom design and logo branding to packaging and even Amazon FBA prep. Get professional-quality padel rackets tailored to your needs, delivered efficiently and ready for market success.

Looking to source custom padel rackets for your brand? We offer expert private label solutions — from design and logo to packaging and delivery. Our streamlined process ensures you get high-quality rackets that elevate your brand and increase your market competitiveness.

Designed for competitive play, our rackets deliver precise control, explosive power, and enhanced spin for top-tier performance.

Precision-Engineered for Competitive Play

Our padel rackets are built for high-level athletes, combining advanced technology with expert craftsmanship to deliver exceptional control and performance.

Advanced Design for Maximum Control

Featuring a teardrop shape and high-density EVA foam core, our rackets offer superior precision, a large sweet spot, and balanced power—ideal for both offensive and defensive play.

Power Meets Spin

With a carbon fiber face and textured grip, players gain effortless power and enhanced spin, ensuring strategic advantage across every match scenario.

.jpg)

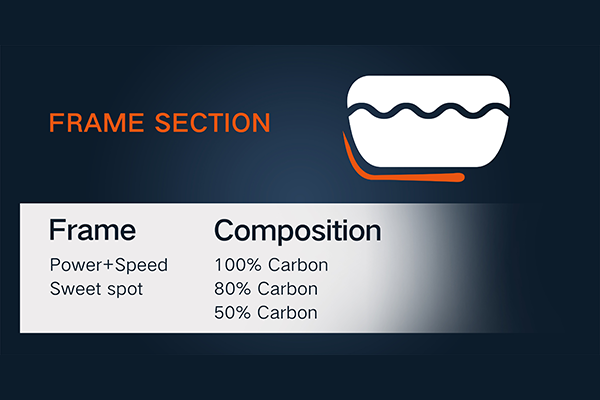

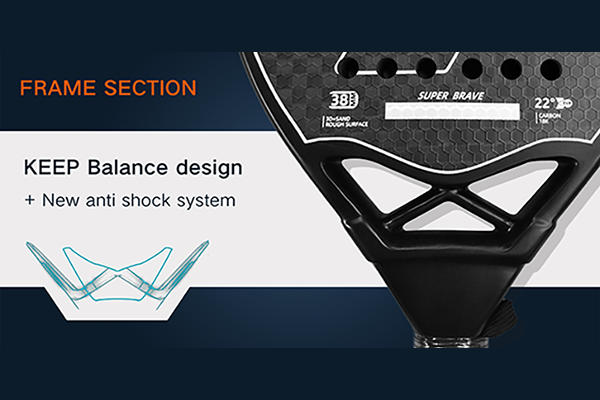

Hybrid Carbon Frame: Our rackets feature a hybrid carbon and fiberglass frame. The carbon provides strength, while the fiberglass adds flexibility, improving shock absorption and reducing arm fatigue.

Wide Sweet Spot: The round shape and balanced design create a large sweet spot, making shots more confident and accurate. This is perfect for beginners looking to improve their game and advanced players seeking consistency.

Ergonomic Grip: The handle is designed for a comfortable and secure grip, reducing the risk of slippage and increasing control. This ergonomic design boosts player confidence and enhances overall performance

High Quality Material and Advanced machine made first-class products

10 years of experience to control products of stable quality with the highest standard.

As a top Manufacturer, we may serve more customers by accepting Low MOQ orders.

Highly Satisfaction with a fast reply within 24 hours * 365 days. 7 years experienced Sales could communicate with you effectively.

Whether you want to have your logo printed on the Pickleball and Paddles or want to design it differently, we can help you.

Our strong productivity and rich experience in sales could guarantee the fast delivery of your order

We offer multiple EVA hardness levels to match different playing styles—balancing comfort, power, and control for every player.

Our padel racket cores are made with Ethyl-vinyl acetate (EVA) and polyethylene. EVA is popular for its durability. Low-density EVA is soft and comfortable, ideal for beginners, while high-density EVA provides power and precision, perfect for advanced players. We use layers of different densities to give players the best of both worlds—comfort and performance. Our EVA options include 13-degree, 15-degree, 17-degree, and 19-degree hardness levels, allowing you to choose the perfect balance for your needs.

When selecting the right EVA for your padel racket, consider the balance between comfort and performance. Key factors include power transmission, user comfort, and stability across different temperatures. Our varied EVA options ensure that you can find the ideal material to enhance your game, whether you prioritize a softer touch or more powerful hits.

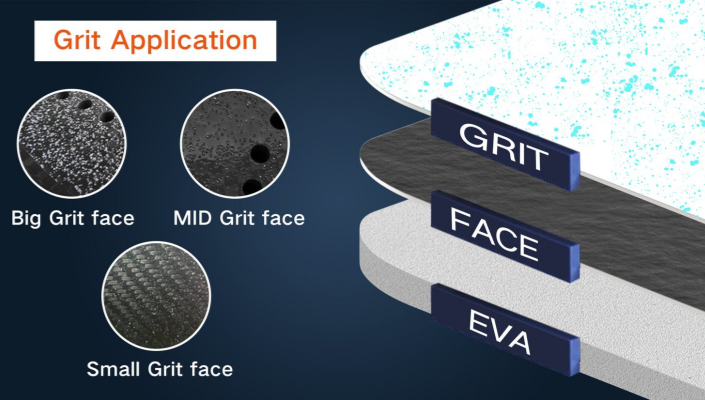

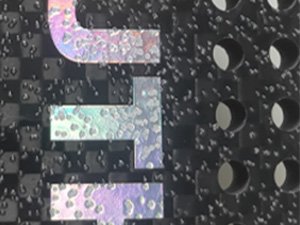

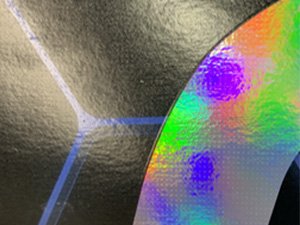

Grit Surface Options

We offer three types of grit finishes—Big, Mid, and Small—each designed to match different playing styles. A Big Grit face provides maximum friction and spin, ideal for players who favor aggressive shots. Mid Grit strikes a balance between control and comfort, while Small Grit offers a smoother surface for players who prefer a softer touch.

Performance-Driven Layering

These grit options are applied on top of a high-performance composite face and EVA foam core. The combination enhances ball grip, spin generation, and overall control. By choosing the right grit level, players can fine-tune their racket’s surface feel to optimize power, precision, and playability.

Our clients and the environment are our top priorities. Delivering perfect results is what sets us apart. For this reason, we use only the highest quality materials. All components are manufactured in Europe, fully compliant with certifications and regulations, and are regularly inspected by our technical and R&D teams.

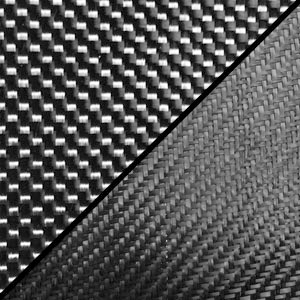

We use premium HEXCEL® carbon fiber, a global leader with 45+ years of experience. Available in various weaves and high-performance grades to meet advanced racket design needs.

Our fiberglass materials offer excellent strength with reduced weight. Multiple formulations and burn levels are available to match different performance requirements.

Our polyethylene and polyurethane foams are lightweight and pressure-foamed for consistency. Offered in various densities and thicknesses for versatile racket applications.

EVA foam provides high elasticity with a firm feel. Ideal for players needing a harder touch. Available in multiple densities and gauges for custom padel racket cores.

We use the latest tubular reinforcements, including aramid, carbon, hybrid carbon, and fiberglass, to enhance structure, strength, and vibration control.

We apply top-grade German epoxy resins to ensure strong and lasting adhesion. All resins meet current certifications for quality and environmental standards.

Our patented foam grip technology minimizes vibration and enhances overall stability, delivering unmatched comfort and performance across all conditions.

Compared to traditional hollow carbon fiber tube designs, our patented foam grip technology greatly reduces vibration transmission during use, delivering a smoother, more comfortable riding or handling experience. This innovation also enhances overall product stability, ensuring consistent performance across varying road conditions and intensities.

Each product is embedded with this proprietary foam structure—developed through precise calculations and rigorous testing. Its exceptional shock absorption and structural stability are hard to replicate, offering a clear competitive edge. More than just a technical upgrade, this design represents our commitment to quality, innovation, and delivering an unmatched user experience.

Our anti-shock padel grip with NOENE inside absorbs and protects against up to 96% of vibrations. This grip effectively shields against impacts, dispersing up to 96% of the negative energy generated by shocks. Its key feature is its viscoelasticity, providing an unparalleled ability to absorb and disperse this negative energy.

The grip is factory-integrated, directly fitted onto the handle of the racket for a slim and lightweight anti-shock solution. The adherent polyurethane coating ensures maximum grip and comfort, offering a secure hold and high precision.

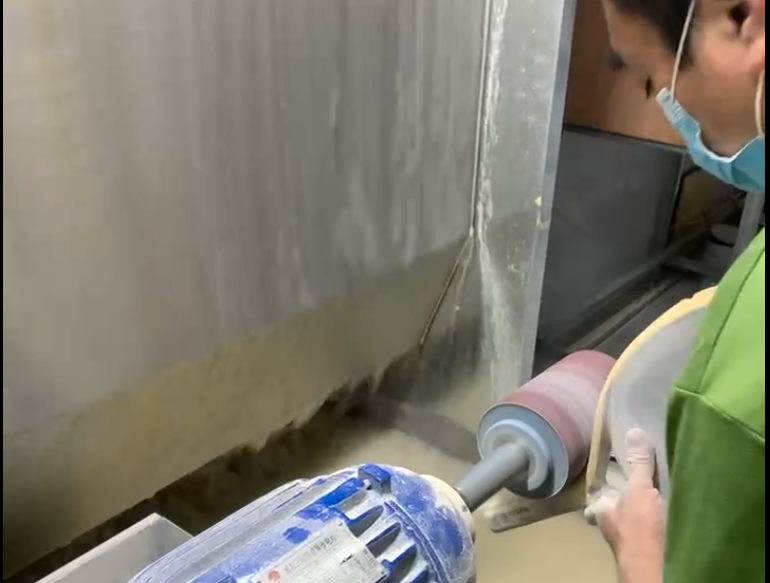

We prepare each racket with precision—deburring, priming, filling, and sanding—for a smooth, flawless finish.

Through the deburring process, we remove any burrs or excess material that may have formed during the molding stage.

Thanks to the priming process—using base varnish or paint—we eliminate any surface pores that may appear.

During the filling process, we repair any imperfections or deformations in every corner of the racket.

In the sanding stage, we create a completely smooth surface, preparing it for the next step of painting and screen printing.

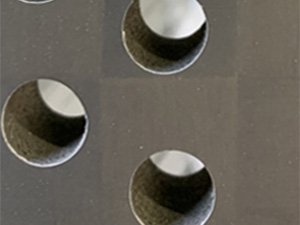

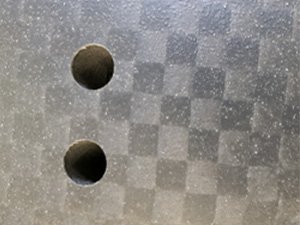

Our cross-drilling technology ensures precise, clean holes across multiple rackets, boosting efficiency, durability, and overall performance.

Our advanced drilling technology allows us to precisely craft multiple rackets simultaneously, significantly enhancing production efficiency and reducing turnaround time. Unlike traditional methods that rely on slow “up-down” drilling, our innovative cross-drilling technique ensures each hole is made with exceptional accuracy.

This technology not only guarantees a high level of precision but also results in rackets with a clean and orderly appearance. The precisely drilled holes allow for seamless integration of components, improving the overall functionality and durability of the rackets. This meticulous attention to detail during the drilling process enhances the performance and longevity of our products, making them a standout choice in the market.

Our established network in Padel Racket China ensures we source premium materials without the premium price tag. Elevate your product line without inflating your budget.

Get a behind-the-scenes look at our advanced production lines, skilled craftsmanship, and strict quality control in action.

Get a behind-the-scenes look at our advanced production lines, skilled craftsmanship, and strict quality control in action.

We are dedicated to providing you with the highest quality custom padel Racket service. No matter what your creative ideas or needs are, we can turn them into high-quality products. Here is our service process:

Contact us now to start your beach racket customization journey. Experience Padelico’s professional service and high-quality products, and turn your creativity into reality!

Fill out the form below, and we will be in touch shortly.