We are a professional beach tennis racket manufacturer providing full OEM/ODM services, including custom molds, logos, colors, and packaging. With advanced production and strict quality control, we help global brands deliver high-performance, durable rackets tailored to their market needs.

Here are some standard designs for your reference, demonstrating our factory’s skill in producing top-quality beach paddles that offer great feel, control, and durability.

We are dedicated to providing high-quality products and efficient services. Our carbon fiber rackets use imported high-density carbon cloth, offering the best combination of firmness, durability, and stability. We are the only factory in China that uses potting molding fine technology, ensuring high precision and consistency in our rackets. This technology not only enhances the aesthetic appeal of the rackets but also provides a solid, substantial feel. When hitting the ball, players will experience reduced vibration, resulting in a more stable and comfortable playing experience. Our rackets are designed to avoid feeling heavy or hard to control, making them ideal for both intense matches and daily practice.

Our racket drilling technology is highly advanced, offering three different hole sizes. We generally don’t recommend using different hole sizes on the same racket, as variations can significantly impact performance and power. However, our precise drilling ensures smooth, burr-free holes even in Kevlar, a feat many factories cannot achieve.

Our high standards rely not only on advanced machinery but also on strict manual inspections to ensure the quality and consistency of each hole. This attention to detail and high manufacturing standards make our rackets exceptional in performance and durability, making them a popular choice in the market.

Our racket’s carbon tube uses a unique triangular structure design, enhancing overall rigidity through three edges. Power Embossing Technology adds carbon fiber ribs to the outside of the frame, further increasing structural rigidity, enabling the racket to achieve stronger hitting power. Structural Power Technology inserts double fibers into the core of the racket, further increasing structural rigidity, thereby enhancing hitting power during matches.

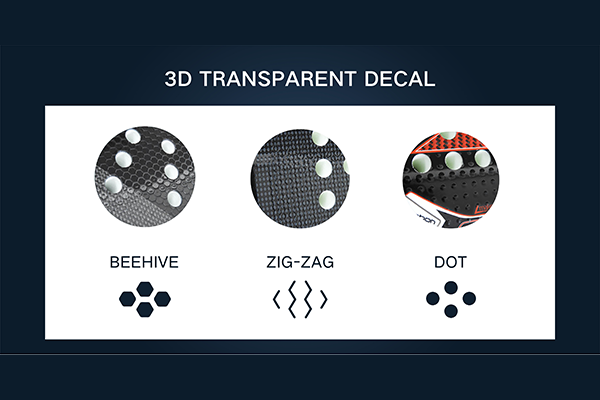

Our factory uses advanced 3D embossing technology to enhance spin during play. The special 3D spin lines on the racket’s face are designed to significantly boost ball spin at impact. The racket also features a gradient surface and unique water transfer decals, making it look great and further enhancing spin. This design reduces vibration when hitting the ball, providing more stability and comfort. Whether you’re a beginner or a pro, this racket will help you control spin better and improve your game. Choose our racket to experience the perfect blend of technology and style.

Padelico provide three EVA materials with varying hardness levels: extra soft, soft, and hard. These choices allow players to select the perfect racket tailored to their preferences. The hardness of EVA primarily determines its memory, or the speed at which the material returns to its original form. Higher hardness results in better memory and increased power, while lower hardness offers enhanced comfort. During fast hits, high-hardness EVA quickly rebounds, propelling the ball at greater speeds. On the other hand, low-hardness EVA excels in low-speed hits or when stationary, providing greater thrust. Choosing the right racket can significantly boost your game.

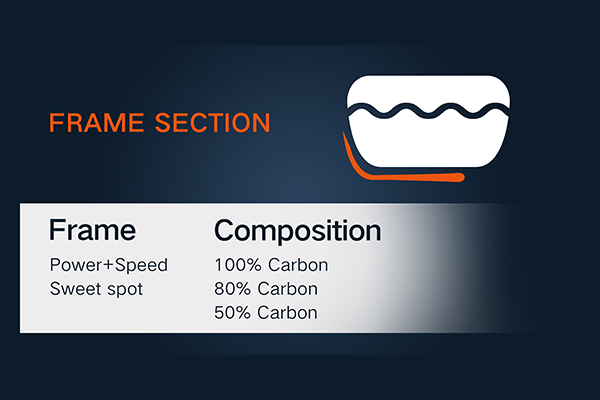

Using 100% carbon fiber greatly boosts the racket’s power and strength. By using this high-performance material in the frame and core, Padelico rackets become stronger and more durable. The high density and strength of carbon fiber help the racket transfer energy better during hits, leading to more power and speed.

Padelico rackets also use advanced technology to improve stability and control. These improvements offer better support during hits, reduce vibrations, and increase accuracy and consistency. This technology is great for power players in intense matches and for players who need stability and control.

By combining carbon fiber with advanced design, Padelico rackets perform excellently at different hitting speeds and power levels. They give players a full competitive edge. Whether it’s powerful hits at high speeds or precise control at low speeds, Padelico rackets meet the needs of different players, helping them perform their best in matches.

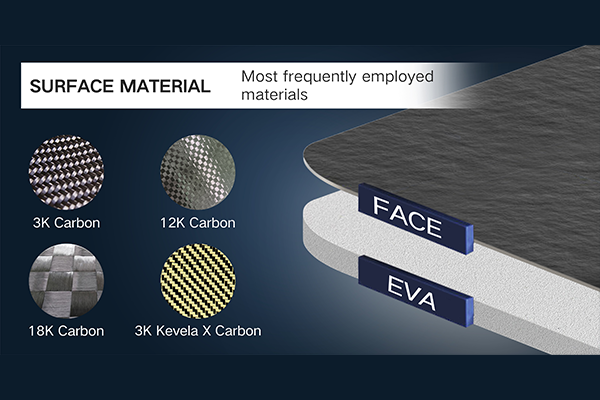

There are various types of carbon fibers, and their “K” number does not directly determine the quality but rather reflects the number of fibers in each carbon fiber tow. This impacts the carbon fiber’s appearance and feel. At our factory, we commonly use 3K, 12K, 18K, and 24K carbon fibers, as well as KEVLAR. Each number indicates the number of fibers in each carbon fiber tow. For instance, 3K carbon fiber contains 3,000 fibers, while 12K carbon fiber contains 12,000 fibers, and so forth. These differences in thickness primarily determine the racket’s rigidity and flexibility, thus influencing the hitting feel and performance. The more fibers there are, the thicker the carbon fiber, resulting in greater racket rigidity, but this may also reduce some flexibility and feel. Notably, all our carbon fiber raw materials are imported to ensure high quality and stable performance. By using premium imported carbon fibers, our rackets offer better control and power during hits, catering to athletes of various skill levels.

The racket has shock-absorbing features. By incorporating damping materials into the structure, it effectively reduces vibrations during hits, improving hand feel comfort and reducing arm fatigue. These advanced technologies collectively enhance the overall performance of the racket, making it an ideal choice for high-level competitions.

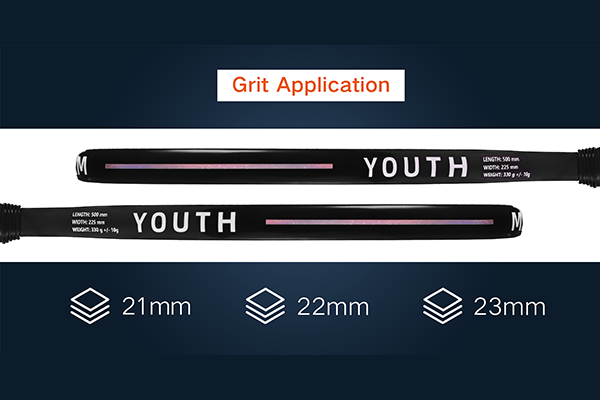

The thickness of beach tennis rackets generally ranges from 19mm to 23mm. Typically, the thinner the racket, the less the ball “bounces,” meaning the rebound force from the racket is lower, which in turn gives the player greater control. Thinner rackets are suitable for players who require precise hitting and control, offering better feel and racket maneuverability. Conversely, thicker rackets are more suited for players seeking higher ball speed and hitting power, as the increased thickness enhances the racket’s rebound force, providing more power during hits. Selecting the appropriate racket thickness based on your playing style and needs can help you perform better in matches. If you need yours own thicness ,you can contact us to open the new mold ,we have the mold department .

Fusce felis elit, semper ac turpis ac, pulvinar consequat arcu. Nullam ac massa vel ipsum tempus tincidunt sit ameti

We are one of biggest Carbon fiber Beach Tennis and padel manufacture factory. We cooperate with many brands, Such as Sexy, Kona, adidas,Bullpadel, Black Crown, Prokennex, Babolat etc.

We arehe only factory in China using potting molding fine technology,at the same time ,our raw material import from japan ,the carbon raw material would be stable much more

We are manufacture for those brand, but we don’t have right to sell it, we signed NDA with them. We only sell customized racket or our own brand , do you have licnese from sexy brand? if not ,i recommend you can sell our brands .

yes, of cousre before the bulk order produce ,we will make the sampels for you and arragne the hole files for your refrerence

In the event of non-human damage, we provide repair services or can arrange for a replacement product. Our commitment is to ensure that you receive the highest level of support and service, thereby maintaining the quality and functionality of your product.

Our EVA materials are classified into three grades: 13-15 degrees, 17-19 degrees, and 19-22 degrees. They feature high elasticity and corrosion resistance, and can avoid chemical reactions with substances such as oil, acid, alkali, and seawater.

We are dedicated to providing you with the highest quality custom padel racket service. No matter what your creative ideas or needs are, we can turn them into high-quality products. Here is our service process:

Contact us now to start your beach racket customization journey. Experience Padelico’s professional service and high-quality products, and turn your creativity into reality!

Contact us now and start your customization journey!

Fill out the form below, and we will be in touch shortly.