If you're looking to build your own padel racket brand, you've probably realized something quickly: this is not like customizing a T-shirt or water bottle. You can’t just print a logo and expect people to play with it, let alone love it. A padel racket is a performance product—and if it doesn’t feel right in the player's hand, it reflects poorly on your brand, not just the factory.

Customizing a padel racket the right way means aligning product design with your market, audience, and brand positioning—every decision matters, from shape and materials to packaging and after-sales strategy.

We’ve helped over 4,000 clients around the world source and customize products from China, including dozens of padel racket brands. Most people who fail in their first launch don’t fail because the racket was low quality. They fail because the racket didn’t fit the player. In this article, I’ll walk you through what real padel racket customization involves—step by step—from strategy to specification to production.

Understand Your Target Market Before You Touch Design

Before you get into cores, shapes, or printing, you need to answer this: who are you building for?

This sounds obvious, but 7 out of 10 new brands we work with don’t have a clear answer when they first come to us. Are you selling to beginner club players who want a soft, forgiving racket? Or to experienced tournament players who want power and edge control? Are you targeting men, women, youth, or unisex audiences? Are you launching a budget brand or a premium label?

Your answers will completely change the specs. For example, a beginner racket typically uses a soft EVA core, rounded shape, and a light balance to reduce arm fatigue. We helped a startup in Spain design such a racket for female club players in the 30–45 age group. They originally asked for diamond-head carbon rackets—until we brought in sample testers and 80% of users said it felt too heavy and stiff. We pivoted the design, and the launch sold out in three weeks.

Without understanding your audience, you risk designing for yourself—not your customers.

Start with the Core: It Defines Feel and Performance

Most people think racket design starts with the shape. But in our experience, the core material is where everything begins—it affects how the racket feels, how it absorbs impact, and how it rebounds.

Nearly all rackets use either EVA foam or polyethylene. Soft EVA offers comfort and control, while harder EVA increases power and ball speed. For most club-level or beginner rackets, we recommend EVA around 17–20 kg/m³. For aggressive or competition-level players, a medium or hard EVA up to 30 kg/m³ works well. The important thing is to never choose blindly—ask your supplier to share the density specs and foam brand. We’ve encountered suppliers using recycled or off-spec foam to cut cost, which leads to uneven hitting zones and premature core collapse.

We once helped a client selling in the UAE who was getting unusually high return rates due to “dead spots” on the racket. It turned out their supplier used low-grade PE foam inside without telling them. After switching to virgin EVA and proper core bonding, returns dropped by 90%.

Always test the core before you approve production. This is where quality starts—or fails.

🔗 Read: EVA Foam Grades Explained – Polymer Database

Frame Materials and Shape Must Match Your Brand Position

After the core, the next key choice is the frame construction and the overall shape of the racket. These affect durability, vibration, and player confidence.

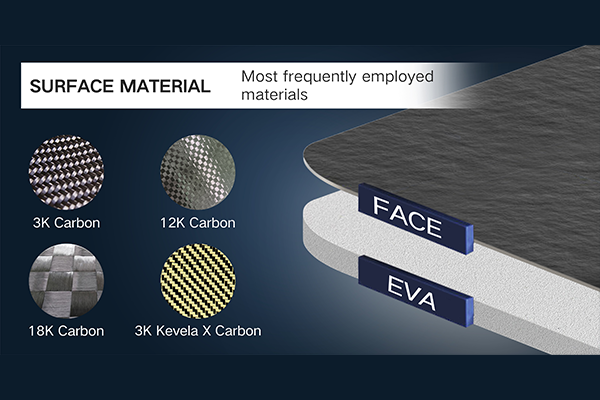

There are three common frame materials: fiberglass, carbon fiber, and hybrid blends. Fiberglass is cheaper and slightly heavier, good for budget lines. Carbon fiber (usually 3K, 12K, or 18K weave) offers strength, stiffness, and better vibration control. If your brand wants to position above $80 retail, we always suggest carbon—at least 3K. Higher weaves like 12K or 18K are best for pro-level or visually premium rackets, but the price and MOQ will rise.

Shape isn’t just about looks. Round rackets offer control and stability—best for beginners. Teardrop shapes give a balance between control and power. Diamond shapes load weight in the head, creating smashing force but requiring skill. A common mistake is choosing a “cool” shape that doesn’t fit the user. One of our Italian clients insisted on a diamond frame for their launch because it looked aggressive—but their target users were casual male players in their 50s. We redesigned with a teardrop mold, and the client later told us that feedback from customers dramatically improved.

Form follows function—don’t let visuals lead specs.

Customization Is Not Just a Logo—It's Your Brand in a Racket

Too many factories will tell you customization just means printing your logo. That’s not enough—not if you want a real brand.

Real customization means designing the full user experience. That includes:

- Pantone-matched frame and string colors

- Custom surface textures (matte, gloss, sandblast, 3D emboss)

- Grip materials and shapes

- Racket edge guards and cap design

- Branded bags or cases

We helped a Swedish brand create a signature look using matte black frames with brushed silver logos and rubberized grips. They kept every visual element aligned across their website, packaging, and rackets. The result? A mid-range product that looked like a $200 racket and built massive customer trust.

Factories will often push you toward “standard molds” and pre-set finishes. Don’t settle. Ask what customization levels they offer. Provide your own design files. And always request a pre-production sample to confirm the look and feel.

Don’t Ignore MOQ, Tooling, and Real Production Timelines

Let’s talk factory reality. Even the best design will fail if you don’t understand manufacturing limitations.

Most padel racket suppliers in China have MOQs of 100–300 pcs for semi-custom orders (using existing molds) and 500–1000 pcs for full custom molds. Custom tooling for a new mold shape can cost $400–$800 and takes 10–15 working days. After sample approval, mass production runs typically need 30–45 days, plus shipping time.

Budget also plays a role. A basic fiberglass racket might cost you $15–$18 FOB. A 3K carbon model with branding and bag can cost $25–$35. Full custom, 18K carbon, premium texture, packaging? Expect $45–$60+. Always ask for a complete cost breakdown, including mold fees, printing setup, color matching, packaging, and QA. We’ve seen clients burned by hidden charges on “final printing” or “accessory packing” just before shipping.

Plan timelines early—especially before seasonal peaks. Want to sell in June? Start the process in February.

Work with Partners Who Understand Both Product and Production

Factories are great at building rackets. But they often aren’t thinking about your brand, your end customer, or your sales funnel. That’s why working with the right partner—someone who can bridge the gap between design vision and factory execution—is critical.

We’ve seen many new brands fail not because the factory did a bad job, but because no one translated the brand’s intent into proper specs and QC. You need someone who can:

- Translate brand positioning into product specs

- Vet and audit factories with real experience (not just Alibaba reviews)

- Manage sampling, pre-shipment QA, and packaging design

- Ensure compliance for export markets (EU REACH, SGS, ASTM)

This is where we often step in. As a sourcing partner with both product knowledge and ground presence in China, we act as the filter between vision and delivery. One brand we worked with went from concept to product launch in 68 days—including sampling, customization, and a marketing shoot with pre-production samples shipped ahead by air.

Padel rackets are competitive—and if you want to stand out, you need more than a supplier. You need a team that understands your brand matters just as much as your balance point.

Conclusion

Customizing padel rackets for your brand isn’t a task—it’s a full strategy. Every design choice you make affects playability, price, perception, and production risk. The brands that succeed are the ones who don’t just want a product to sell—they want to create a product that players love, remember, and talk about.

We’ve worked with brands at every stage: from first-time entrepreneurs with zero samples, to sporting retailers needing private-label expansion. If you’re serious about building a padel line that wins both on and off the court—we’re ready to help.

Contact us today to get a custom proposal, review materials, or request a pre-production sample. Our sourcing team will guide you from concept to launch—step by step.

👉 Talk to our team now